Seatronics

The marine technology specialists

As the industry’s leading technology specialists in subsea electronics, Seatronics provides marine electronic equipment to the global subsea market via rental/hire and purchase options.

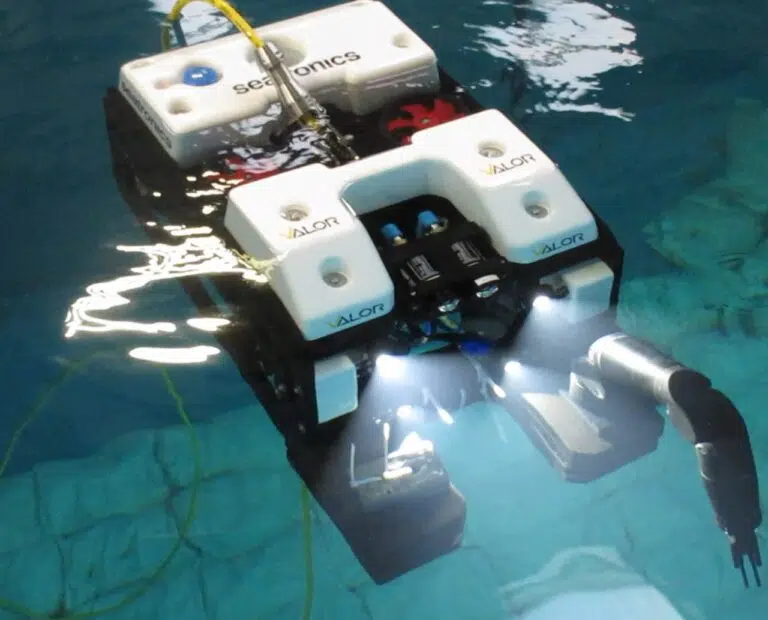

Seatronics are trusted by their clients to provide innovative technologies and to develop bespoke solutions utilising our vast experience of subsea electronics, integrating and packaging equipment to meet varying subsea challenges. Their latest development, the VALOR, is the most powerful observation ROV available. In addition to equipment rental and sales, Seatronics offers a number of trusted services including manufacturing subsea connector and cable assemblies, asset management and state of the art calibration facilities.